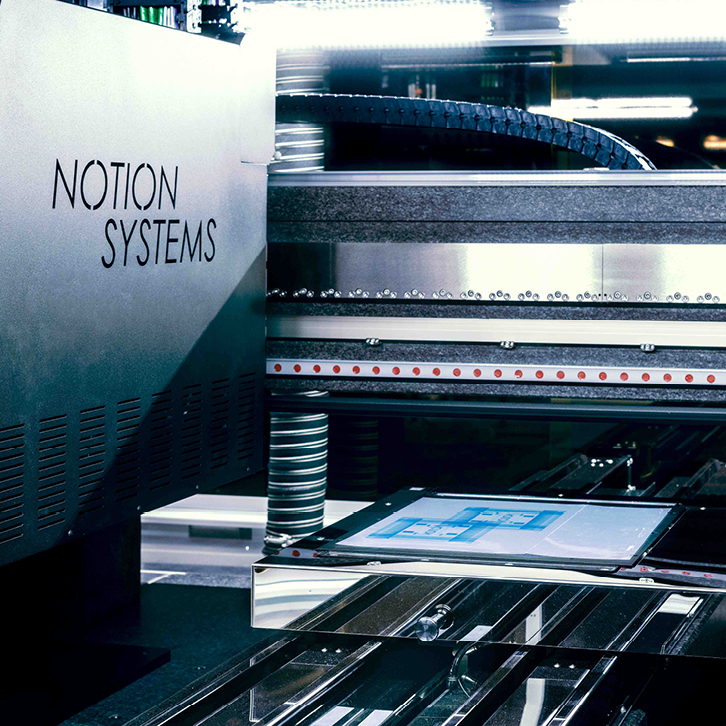

We develop and build inkjet printing systems for functional materials

and scale processes from laboratory to industrial production

Cookies helfen uns bei der Bereitstellung unserer Website. Durch die Nutzung der Website erklären Sie sich damit einverstanden, dass wir Cookies setzen.