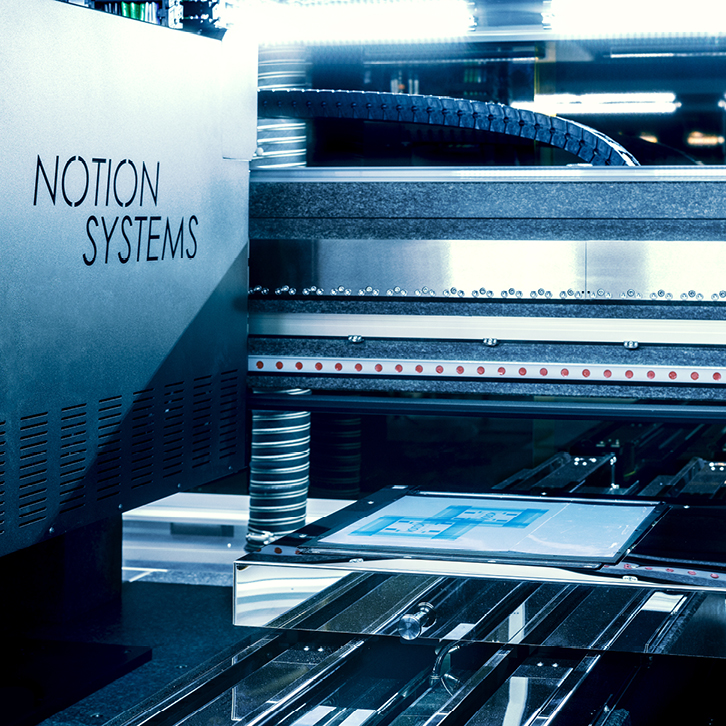

We Scale Inkjet Processes from Lab to Fab

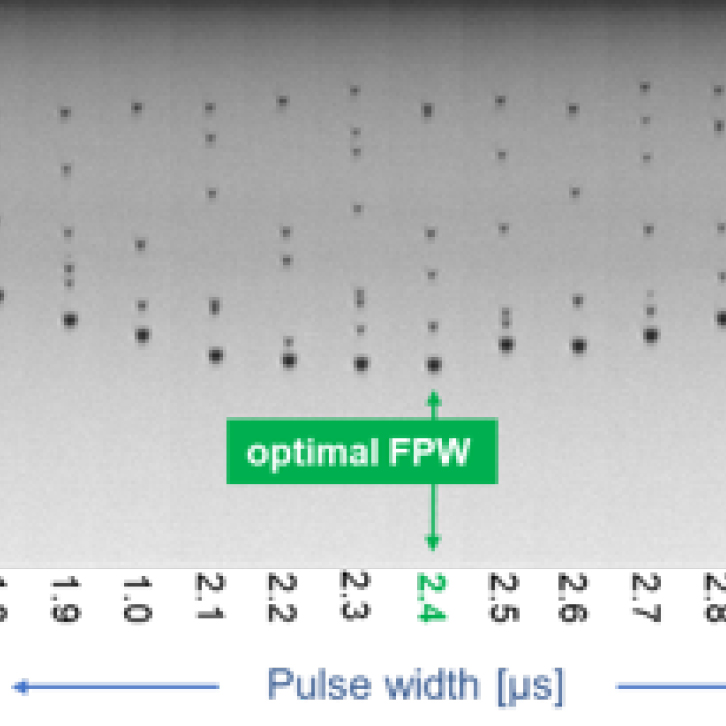

By systematically adjusting various parameters, process development can enhance the printing quality, efficiency, and reliability of inkjet printing.

This is particularly important for industrial applications, where consistent and high-quality printing is required for mass production. Additionally, process development can help minimize the environmental impact of inkjet printing by reducing ink and energy consumption and waste generation.

Process Development

helps optimize

various parameters

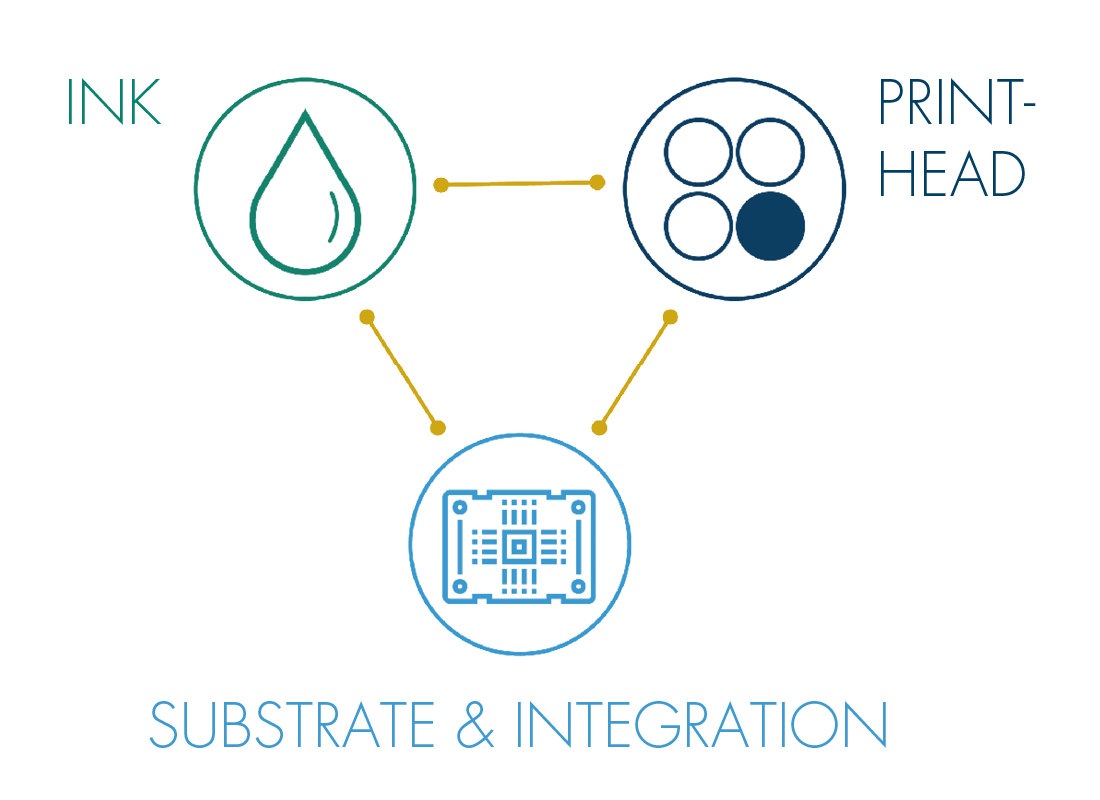

The inkjet triangle

An inkjet production process comprises three main components: the ink, the printhead, and the substrate.

Notion Systems analyses and optimizes these components individually, as well as their interaction in order to establish an inkjet process with stable and repeatable results in industrial production.

Scaling Process

Advantages of Inkjet Printing

Inkjet is a non-contact, digital printing technology which creates fine structures of 30 microns and below. The fully digital non-contact printing enables wet-on-wet processing without the need for masks or screens.

Inkjet is used to replace established subtractive process sequences and reduces waste and energy consumption, which makes electronics production more economical and ecological.